|

| Hey greenandyellow,

Just coincidently, I had another fellow that was going through a similar situation, and if you wanted to read through some of it to give some context as it'd be a very similar situation to yours.

https://talk.newagtalk.com/forums/thread-view.asp?tid=1096193&mid=10...

What it comes down to is two things:

1. Using a very large nozzle, despite being the finest possible (e.g. ER series as you mentioned), you will get pinned into the situation you noticed. Even as fine as you can get, the spray starts getting rather coarse. While drift reduction is fine enough, you'd still opt for a heavier balance towards coverage than drift reduction (especially in fungicide). As far as the ER series, its a conventional flat fan nozzle, and would produce the same kind of spray as like a Teejet XR nozzle, so it isn't really a 'coarse' nozzle series/type.

2. With your solenoid, the system is good, BUT it does have a max flow capacity with the solenoid. Effectively, once you start getting above like 1.0-1.25 us gallons/minute flow rate, you start getting pretty darn nasty pressure drop. This plagues all PWM solenoids, but some valve specs are a bit different (some are better for pressure drop, but many are the same relative max flow).

So, this COMPOUNDS the issue from item #1 (larger nozzle size = larger droplets on average). So, an ER110-125 at 60PSI shown in your cab is ACTUALLY going to be providing the nozzle closer to 36PSI (so 24PSI pressure drop). This is why the spray quality gets coarser than you'd hope for.

With issue #2, it would still plague the nozzle setup with a twin nozzle setup unfortunately (as the pressure drop is based on TOTAL FLOW), but the effects would be lesser than a single nozzle. Depending on the specifics of your applications (whether it is primarily wheat/cereal fungicide), there might be merit to focusing in on angled nozzle options.

So, for your situation, a few ways to help apply better:

1. Technically you can slow down. This lets you use a smaller nozzle, but again, I understand you have to keep efficiency, but I wanted to point it out. Not the point of what you are wanting to do, but I often forget to actually mention it.

2. Split up the nozzle flow. So, with your sprayer, you likely have a stacked nozzle body setup. Sometimes folks think the stacked nozzle body (which is AUTO-RATE controlled if it is in OPEN position) is only for liquid fertilizer top dressing. It can also spray chemical at the same time as the pulsing nozzle, and it is an effective way to optimize applications that are high rate (e.g. 15GPA+) and higher speeds (15mph+) that otherwise could not be done through a solenoid without a ton of pressure drop.

In newer Case IH machines (2019+, and maybe even 2017+ if you are using Raven monitor), in the spray application menu on the monitor, there would be a drop down where you'd be able to swap the spray style to 'HIGH FLOW MODE', which then asks for which nozzles are pulsing and which is non-pulsing.

So, to split a nozzle, this isn't the same as doubling a 10GPA PWM nozzle and having one on the non-pwm nozzle. For the non-pwm nozzle, since it is autorate controlled, think of it being stuck at 100% duty cycle. It is also based on speed and pressure. So, if you are speeding up, your pump will have to increase pressure nominally.

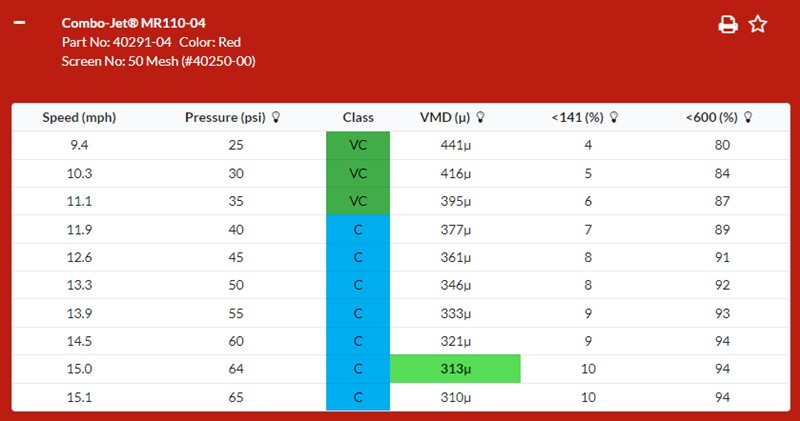

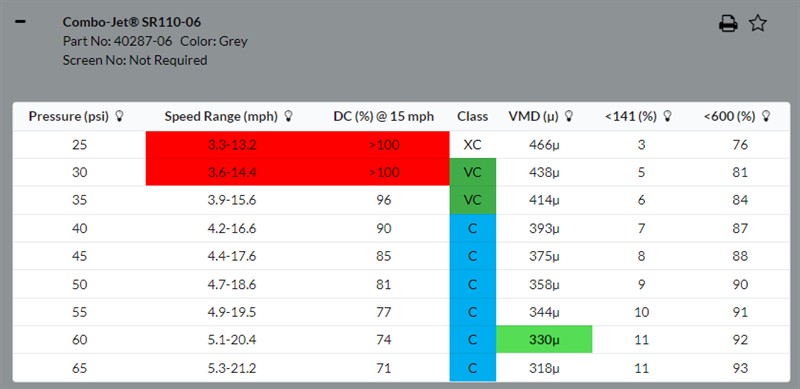

To minimize any 'less ideal' effects, we'd try limit the non-pwm nozzle to less than half the size of the PWM nozzle flow. (e.g. 10GPA PWM at 15MPH might be an SR110-06, and 10GPA non-PWM at 15MPH might be an MR110-04). For the less ideal, the duty cycle of the PWM nozzle might start varying a little bit more when you are at your non-average speed, but generally speaking the benefit would outweigh that. I'd usually just keep a non-PWM nozzle selected that is applying at the max speed at a higher pressure to minimize any of that goofiness.

3. Split up the nozzles with an adapter (BOTH PWM): while this might be an option in that you could use something like 1x SR110-06 + 1x ER110-06, which would make up almost the same size as the 110-125 that you were looking at before, it'd still be better to use the 'HIGH FLOW MODE' of your sprayer and use PWM + non-PWM at the same time.

I'm currently underway getting 'DUAL NOZZLE Tip Wizard' finished up, so hopefully I can have it online and in the app as a beta feature that will make those kind of selections easier as it would show the nozzle specs AFTER the pressure drop of the joint nozzle size. So, this will help both in being able to search for a "PWM x 2 - Double Down/Angled", or 'PWM + non-PWM', or 'Rate-controlled x 2 - Double Down/Angled/Stacked' style of spray nozzle selection.

My favorite layout would be the PWM + non-PWM. In your case, an SR110-06 (PWM) + MR110-04 (non-PWM - COULD BE SWAPPED TO A DR110-04 depending on what you were needing for incrop herbicides) might be a solid setup.

Generally you'd be keeping your driftable fines <10% (or so) and keeping your coverage factor >90%, with the means to reduce drift when you need it.

I probably skimmed over some of it, but let me know if that makes sense or if you have any other questions,

-Lucas

(MR110-04_10GPA HALF_nonPWM_15mph (full).png) (MR110-04_10GPA HALF_nonPWM_15mph (full).png)

(SR110-06_PWM_10GPA (full).png) (SR110-06_PWM_10GPA (full).png)

Attachments

----------------

MR110-04_10GPA HALF_nonPWM_15mph (full).png (53KB - 18 downloads) MR110-04_10GPA HALF_nonPWM_15mph (full).png (53KB - 18 downloads)

SR110-06_PWM_10GPA (full).png (53KB - 15 downloads) SR110-06_PWM_10GPA (full).png (53KB - 15 downloads)

| |

|

Wilger spray tips help

Wilger spray tips help