Couple easy sheet metal projects from this afternoon. Been wanting a sheet metal brake for a lot of years really could never justify the expense of a full blown pro model but always lacked a way to get nice even bends for simple but practical items like these. Been starting out doing a couple simple things getting a feel for how much metal to leave for the actual bend. Good way to improve my metal fab skills. Bought one on sale a while back at Harbor Freight and again I think this fits into you can't afford to buy the best of everything especially when you know it won't be getting used everyday.

It's rated for 16 gauge metal and that is what I used for these couple simple projects. I had inquired earlier about how to repair this area in a recently acquired wagon. https://talk.newagtalk.com/forums/thread-view.asp?tid=750603

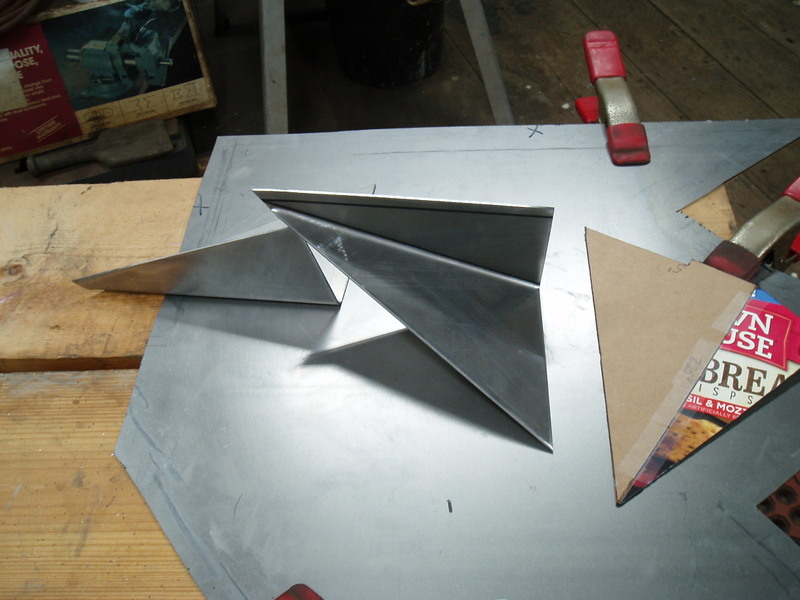

I could not just cover this with sealant and decided to see if I could make some repair patches that would cover/ reinforce these areas. The first step is to make a couple patterns out of thin cardboard to test fit and get the shapes right. It's easier to do in a couple pieces then tape them together for the finished piece that will need bent.

Cut the metal with a jig saw and got the edges all squared up to the cut lines. The vertical piece throws the angle off since you are dealing with a compound angle. Made them a bit oversized so they can be trimmed to fit exactly.

Next I thought I would take on a small project Paul Butler had inquired about a while back about finding hydraulic tip holders. Was not sure the 16 gauge would be sturdy enough just as a flat piece. So I bent the edges back 1/2" or so on a flat sheet. It was amazing how rigid that made the piece.

Then I measured my old style JD tips in a couple different places. I needed a 15/16 hole for them to pass though and a 13/16 channel to slide in. Made the hole and channel slightly undersized and gradually eased up to the correct dimension with a reamer for the hole and filing the slot after cutting with a jigsaw.

Here is how it will work it will be bolted fast to the cross rail on the wagon and the bent wings extend off the back to add rigidity.

It would be pretty easy to modify this to fit anything that you wanted to install a tip holder on. It's basically the same style found on the 750 drill although that might be slightly thicker material.

Hope this gives others some ideas. All in all very happy with ability of the HF brake to bend this material. |

Easy sheet metal projects: pbutler you might like (pics)

Easy sheet metal projects: pbutler you might like (pics)