Can anybody give some opinions on these older JD chisel plows and there durability or weak points. These would be trailer type and not 3 point mounted. A 1600 appears to pull from 3 points all pretty much from the front bar relying on the rest of the pull to be transferred back through the other bars of the frame. Seems there is a piece of I beam on top to transfer this pull back to the other bars. Walking tandems ? good or bad ? the ones on this 1600 seem very long front to back which look like a weak point skidding sideways when turning shorter ? That lower bar center bar in the hitch looks like it would be a drag point as low as it is ? Image courtesy of the web.

The 1610 appears to have attachment points near the front then another set of attachment points further back in the framework with I beam tongue members which ought to distribute the stress points at mutiple points in the frame work. This one also has the single tire instead of the walking tandems. Image courtesy of Machine Finder

I've tried to transition mostly to no till but still have an occasional field I need to chisel or to work down tile lines etc. Currently have a Oliver 458 large base unit with the wings I took off my small base White 458 to give me a 16 ft mounted chisel plow behind the 8300. It's a real pain to hook up as the Oliver / White mountings are not the right dimensions for a Cat 2 or 3N quick hitch. This means removing the quick hitch and hooking up to the 3 point arms directly plus the need to use bushings in the lower arm balls because of the Cat 2 pins on the chisel. Very difficult to get hooked up and in and out of storage. On numerous occasions in hard ground where it gets to bouncing up and down I have sheared off four 3/4" Grade 8 bolts on the lower arm mounts. I have added 2 additional pieces of tubing between the second and third bars to reinforce things and the front bar was already reinforced with an additional tube inside the front bar. I also added some side plates to the top link area and minutely offset the alignments to take the slop out of that area and give more wear area for the pin. I also added some truss rods to the outer added on extensions to give some more support. http://photos.imageevent.com/vprb/temporarypictures/large/PB100008.JPG

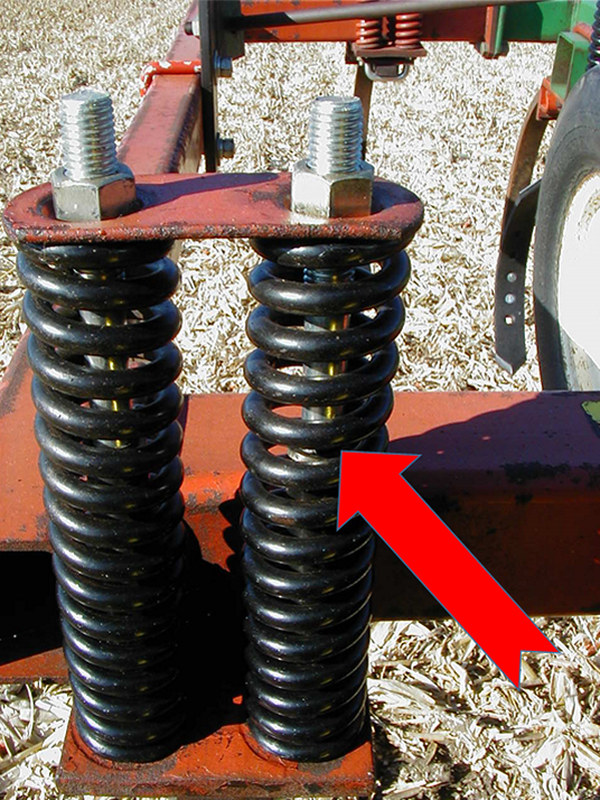

My pivots are getting very worn ( blue arrow and they are not actually a real pivot just sort of a v shaped piece that rocks back and forth) and when the shovels pivot up and back (red arrow) as they work it causes the double springs to pitch forward (purple arrow) this allows the insides of the springs to wear on the U-bolt spring retainers and also as the U- bolts are drawn down through the spring holder plates this eventually thins them and wears them through.

I cut pieces of black pipe to slide on the U bolts inside these springs to help with the wear which helped some but eventually those wear through as well.

The springs and U bolts are quite expensive through Agco parts. So I am either faced with buying some different used style shanks and using them on my current frame and perhaps getting some lower mounts built out of thicker material that are the correct dimensions to ease hookups and utilize the quick hitch Or going to a different style chisel plow. Won't be used on that many acres so price is a top concern but don't want something that I am going to pull in two with 200 + hp MFWD out front. Are the single spring JD shanks more durable with re-buildable wear points ? When did tru- depth standards come into play and how are they identified ? Were there different version of these standards regular vs heavy duty and what were the difference in trip force ? How tough are the JD single coil springs. The Agco ones are okay when new but seem to crystallize and break a little too easily to suit me which means they then collapse in overall height. Realistically how much hp per shank would be needed in heavy clay and sticky black ground with a 1600 or 1610. This 16 shank 458 can stop the 8300 in really tough conditions "here". Perhaps go with a 13 or 14 shank pull type model ? The 3 point mount is very maneuverable and you can work an entire field and not leave a tire mark in it not so sure that would be possible with a drawn type. Just wanting some input on the 1600 and 1610 models and any known issues or things to watch out for. |

Older JD chisel plows 1600 vs 1610

Older JD chisel plows 1600 vs 1610