|

Dodge Co, Wi | Jim,

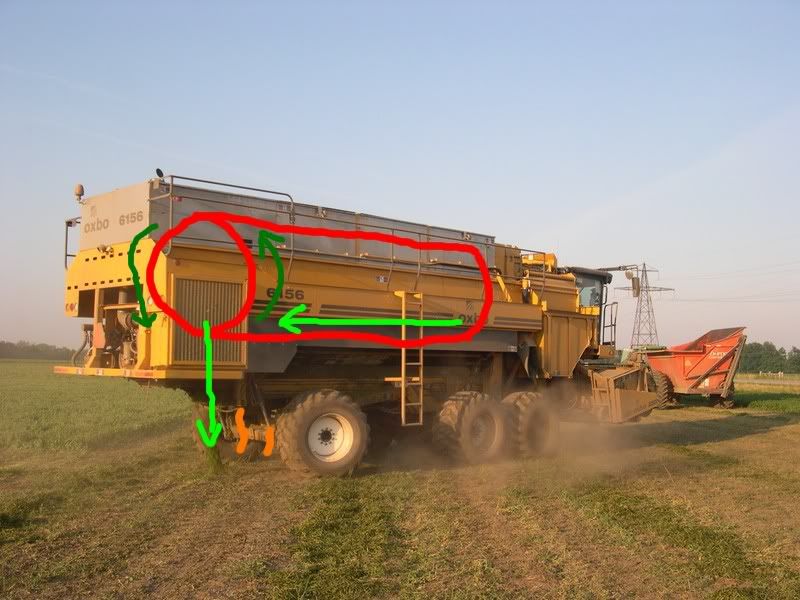

it's just not very feasible to add. It would require mounting it to the rear axle to avoid interference with the levelling of the machine and be rather beefy to handle the mass of the vines/pods and getting it to only spread a 10' swath so as not to cover other peas it would spin so slow that the vines would just build up on it and burn out hydraulic motors. Also it would be in the way of climbing up the rear of the threshing reel to clean out plug-ups, as well as what Jon mentioned about checking for unthreshed peas.

the vines/pods just fall out of the end of the threshing reel and there is only about 18" of clearance between the engine and the end of the drum. The space between the two orange stripes changes constantly it will get shorter as the machine travels down hill and wider going up hill.

The best way that I've seen to deal with the windrows is either to bale them, blow them into a wagon or run over them with a flail chopper just blowing/spreading them up in the air, once the rows have dried crispy they really blow apart with a flail mower.

didn't see we had beat it to death, oh well. I know it is definitely a topic that gets brought up every year with the engineers from oxbo, as it would be nice to solve, i wish it were as simple as it looks to be.

Edited by Lenders 6/22/2009 23:02

| |

|

Pea Harvest started in Southern MN a Few Pics

Pea Harvest started in Southern MN a Few Pics