Today was the first opportunity to run some beans with the 6620 TitanII and 920 platform combination.

Some first day observations. Combine had no trouble running or lifting the head & the extra width and extra capacity is nice. Combine does not sound as if it is struggling at all as far as threshing the extra material either. Not setting any speed records but I prefer slower ground speeds to do a better job cutting and watching out for things. Within the first couple hours the rock dam made the first save. I spied a rock being held back by the hose right behind the right hand cab post in a blind spot. I saw beans piling up and scooting there and sure enough a double fist size rock was being held back by the hose.

No issues with shaving the beans off at ground level either. With the 24.5 X32 tires it cuts every bit as close as the 915 did.

Chopper vanes are all set at about the widest setting. Wind was blowing very hard from the west so that may have affected the spread. Seems to cover about 18 -19 foot of the swath. Small area between passes that is not covered. Seems to be evenly distributed and spread though. This is with a TSR fine chop rotor and new longer style updated fixed knives.

Only minor issue seems to be with the pipe reel instead of the tear drop reel I had on the 915. Can't say I'm enjoying the pipe reel all that much. While the ends seem to be fine without any wrapping issues the spiders in the middle of the reel seem to catch and drag bean stalks around. Once they start wrapping they get tighter and tighter as the pipe goes around and they pick up more and more and make quite a wad. I had more issues with wrapping with this pipe reel mid span than I ever had with the tear drop reel. I need to run the reel back against the auger and fairly low. This keeps material moving and feeding evenly as the rock hose dam does impede the flow of material some. (I won't give that up though.) The issue always startes where the reel spiders attach to the pipe.

Was wondering if somebody else has ever experienced this or not. The pipe bushings are tight and not worn hardly at all.

I see the fingers on either side of the spider and bushing is a finger and half paddle ? are these supposed to be finger and full paddles ? Seems the half paddle leaves the troublesome gap where stuff starts to wrap.

It seems to me I will need to come up with some sort of spacer that is larger than the pipe bushing to keep material pushed away from this area. Much like the disc shields I made for the ends of my 915 work.

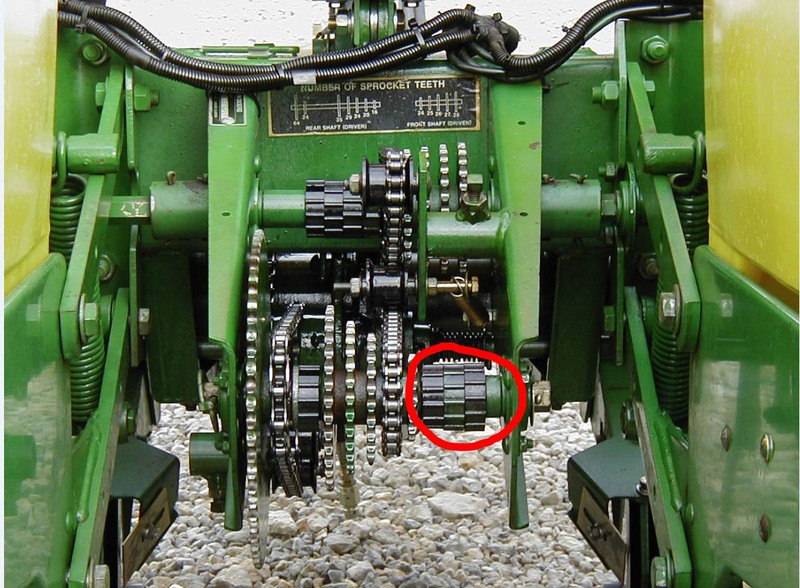

I thought right away about the rubber spacers on the 7200 planter transmission or the ones between the HD down force springs. I think whatever it winds up being it will need to spin freely, be wide enough to fill this gap area and a larger diameter than the bushing area of the pipe /spider connection to keep material pushed away from this pinch point.

Other than the irritating reel wrapping I'm pretty happy with how they work together so far. Wobble box drive on the 920 seems a lot smoother than on the 915 as well with less vibration.

|

JD 6620 and 920 first run evaluation

JD 6620 and 920 first run evaluation