Agent Orange: Friendly fire that keeps on burning. | I started out with a small 8X14 lathe. It worked OK for a lot of the things you mention but like a lot of things, bigger would have been better so I sold it and bought a HF China made 14X40. It weighs right at a ton, so is fairly rigid. There is virtually no one around here with a lathe and buying used was out of the question for me. I knew next to nothing about them when I started looking, so would have been really easy for me to buy a worn out piece of junk, even after I would have looked at it in person. I paid $3,000 for this one and have been happy with the accuracy.

I added the DRO after I bought the lathe and that's not included in the $3K.

If you're looking at a used machine, areas of some concern would be the headstock bearings but those could be replaced fairly easily. The bigger worries would be the bed ways and leadscrews.

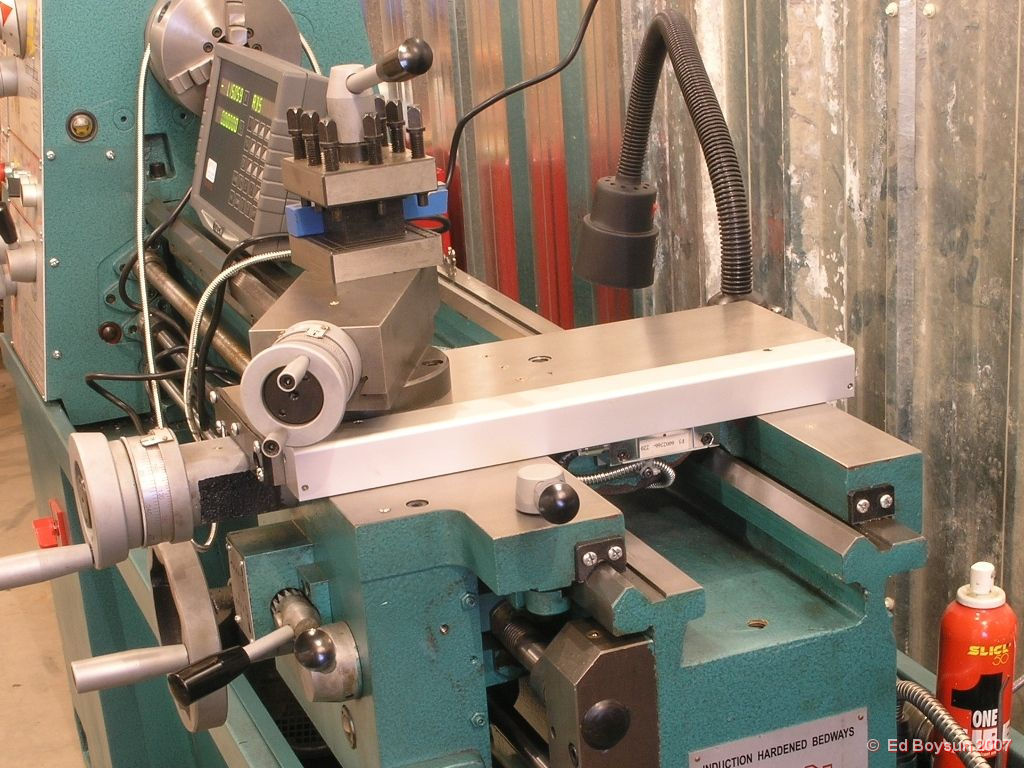

Older lathes often had unhardened ways that were prone to wear and dings from dropping stuff on them. Here's a pic of the carriage on my lathe that will give you an idea of what I'm talking about:

This is the part of the lathe referred to as the carriage. It moves along the length of the bed and is held true by the triangular ridge on the front of the lathe and the box like way at the back. A lot of times, the carriage spends a good part of its working life within a foot of the headstock and chuck. A lot of back & forth in this area with improper cleaning and lube can cause more wear in this area than will be found in the area farther from the chuck. There is provision to snug up the way on the back but not much can be done to keep the front way holding the tool at the proper distance from the work axis. Additionally, if you get things snug in the worn part, the carriage will be too tight when it moves toward the unworn end of its travel.

The next part of the carriage is the middle slide shown that is referred to as the crossslide. It sits on dovetail ways and its position is controlled by a leadscrew turned by either the hand dial or a gear that turns in relation to the rotation of the lathe arbor. That dovetail way is also often subject to uneven wear because there is usually a range of its travel is more used than other parts. The leadscrew for the crossslide can wear uneven too and when these are tightened to compensate for wear, they're too tight at the ends. Very hard to correct for. Then the top section of the carriage has one more movable part that sits on another dovetail way and is controlled by a leadscrew. Expect similar wear issues on the compound slide due to not being always used for the full travel.

A real accomplished machinist can compensate somewhat for some of the wear problems. Since I was a long way from that, I decided to make my life simpler by not needing to compensate for worn out stuff.

As for parts for older machines; some of the replacement bearings can be found without too much hassle. If its a part that is usually subject to wear or breakage, then your chances of finding a good one on a donor machine aren't good and if its been out of production for a while, chances of finding a new or good one are poor. At least a newer import machine still has most oddball parts available. |

Metal lathe for beginners

Metal lathe for beginners