Been a while since I posted, will see how this is accepted this time around or if it draws a similar response like my last one did. This same info.has now been added to the Titan II combine wiki on Agtalk+ Last year (2009) I installed the TSR knife upgrade for the Titan II machines. It was definitely an improvement over the old sickle sections. However I was looking for even further improvement in the shredding of soybean and wheat stubble for faster decomposition and better distribution to try to no till into in the spring. So for 2010 I bought the TSR fine chop rotor from Spallinger Combine in Bluffton, Ohio who handle the TSR line of parts. http://http://www.spallingercombine.com/ Here is a picture of the TSR rotor in a well constructed wood frame to prevent damage.

The bearing on the end where the shaft speed monitor mounts came off pretty easily. The drive pulley came off easily with a gear puller too. However the bearing on the pulley end was frozen to the shaft. I had to cut the back half of the bearing holder to have room to get the puller behind the bearing. Even with the puller and heat from a torch it would not budge. I cut away the outer race and proceeded to cut the inner race in about 4 different places with the torch being careful to not knick the old rotor shaft. Even then it required the puller to finally get it off the shaft. Looks like it was an original bearing from 1988. Here are a couple pictures of the cut inner race.

I painted the ends of the old rotor shaft to protect them from rusting and will keep the shaft in storage for a spare or emergency.

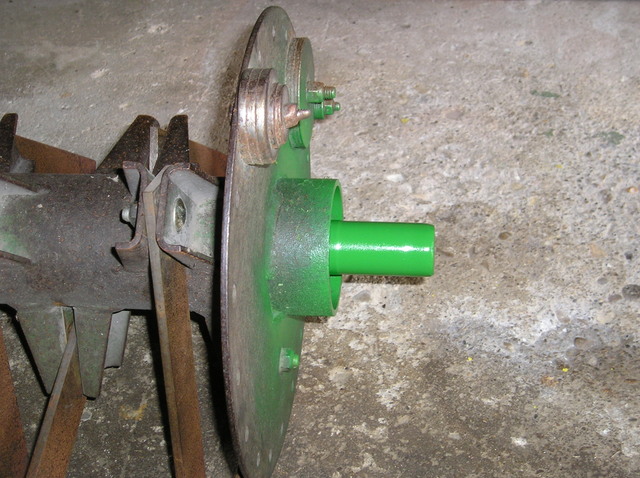

I noticed there was some difference in the length of the smaller tube on the ends of the old rotor compared to the TSR one. These ride inside another short tube welded to the inside of the straw chopper side panels. They are made this way to act as a dust shield and to prevent material from wrapping on the ends of the rotor.

After setting the TSR rotor into place I became concerned about the shorter pieces of smaller diameter pipe not fully seating into the pieces on the straw chopper side sheets.

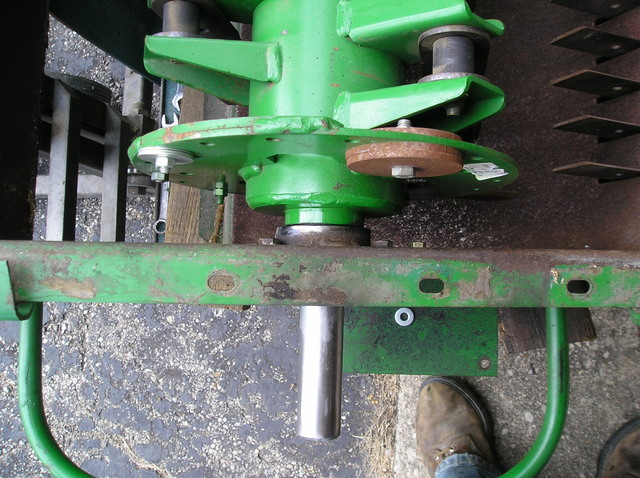

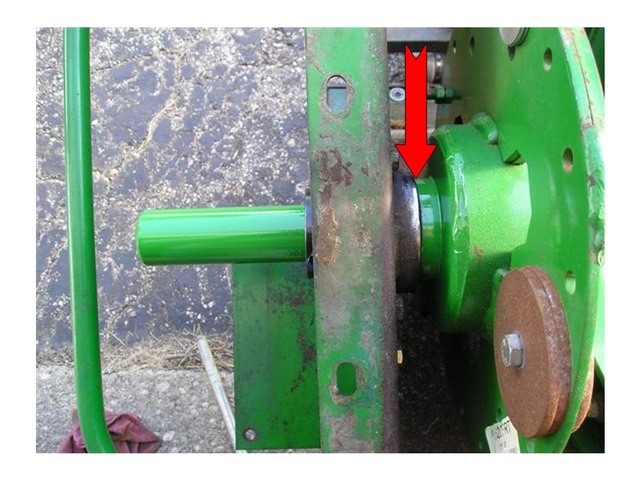

I called Spallinger to inquire about this issue and they said that nobody had ever had any problems in this area but suggested I call the TSR folks to see what they had to say. I called the kind folks at TSR and explained what I was seeing and even sent some email pictures so everything was clear. They said that this was normal and that they had never had any problems in this area. It was very refreshing to talk to people that understood the issue and were very prompt and helpful in addressing my concerns. Before I installed the bearings when I tried to set one end inside the pocket on one side when I would lift the other side to try and set it in the other side would fall out. At this point I installed the new bearings in the 2 piece bearing holders and bolted them up to the sides of the chopper. I did not install the locking collars yet as I wanted to make sure I had the knives properly aligned to miss the fixed knife bar. Here is a picture after centering the rotor in the housing to get the best possible clearance. I even tried reversing the knives on the fixed bar to make sure the clearance was still acceptable. Here is a picture of the rotor centered. I don't think there is going to be much pass through the chopper that does not get shredded up pretty good. The TSR rotor has twin sharpened knives in place of every fixed blunt hammer in the old OEM chopper.

After centering the rotor I installed the eccentric locking collars on the bearings. The side with the speed sensor the small diameter pipe rides slightly in the pocket. The pulley side is just shy of riding in the pocket. Hopefully there will be no issues but it was most important to center the rotor in the housing as there is not much room for error between the rotor knives and the fixed knife bar.

Here is one last picture of the completely installed TSR fine cut rotor for the Titan II machines.

|

TSR fine cut straw chopper rotor install on 6620 T2 pics (dial up warning)

TSR fine cut straw chopper rotor install on 6620 T2 pics (dial up warning)