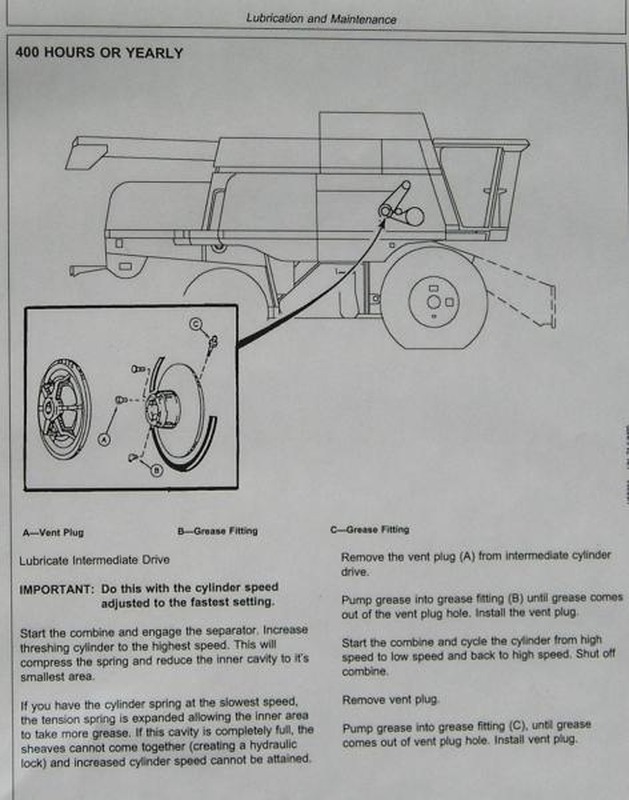

Check the hose from the zerk bank to the bearing. Sometimes old grease can get hard and block the hose/passage. Sorry to hear the tool did not work those pumps can get incredibly tight especially if not removed for a long time. you did the right thing rather than risk breaking it off. Also a good time to grease the intermediate cylinder drive. It's described in this reply. https://talk.newagtalk.com/forums/thread-view.asp?tid=583316&posts=1#M4817288 As a reply in this thread https://talk.newagtalk.com/forums/thread-view.asp?tid=583316 Which points to an earlier discussion by Lil Hoss. http://talk.newagtalk.com/forums/thread-view.asp?tid=62445&=1#M440409 The manuals are not clear on this procedure and it must be done with cylinder at maximum speed.

Here is the associated pic and the procedure from a later series book.

|

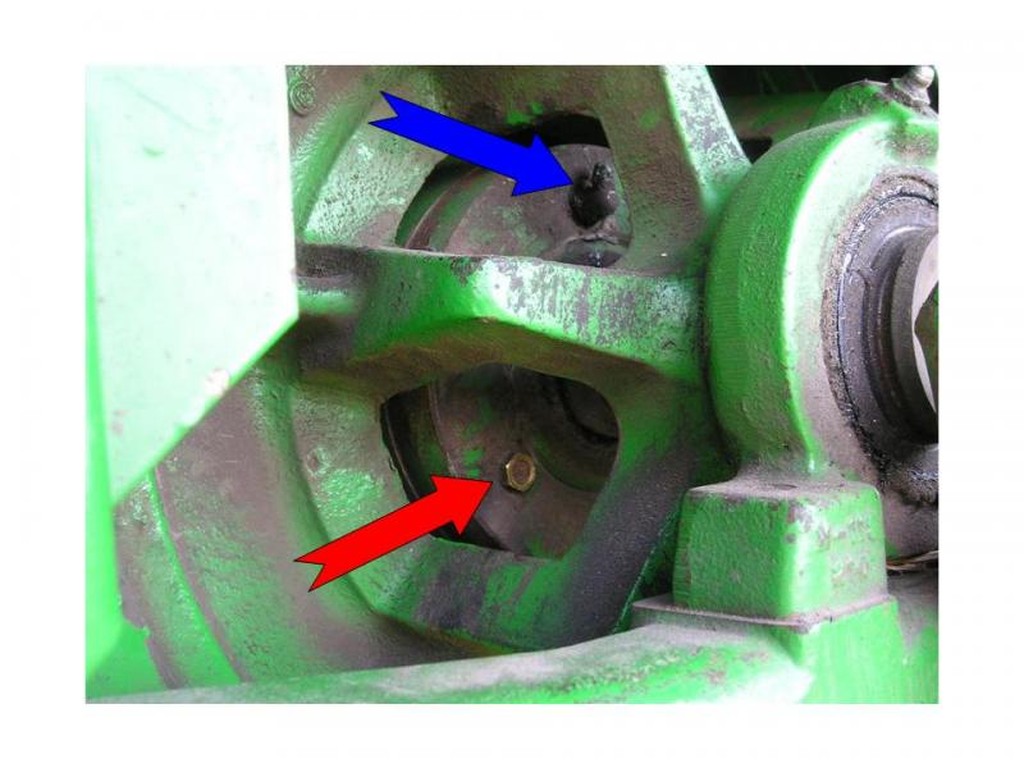

7720 primary countershaft bearing clutch side

7720 primary countershaft bearing clutch side