| ||

| AgTalk Home | ||

| ||

Pea Harvest started in Southern MN a Few Pics Pea Harvest started in Southern MN a Few PicsJump to page : 1 Now viewing page 1 [50 messages per page] | View previous thread :: View next thread |

| Forums List -> Machinery Talk | Message format |

| 2+2, MN |

| ||

New Ulm, MN | First day running for the season (DSCN2479.jpg) (DSCN2478.jpg) (DSCN2472.jpg) Attachments ----------------  DSCN2479.jpg (61KB - 1158 downloads) DSCN2479.jpg (61KB - 1158 downloads) DSCN2478.jpg (43KB - 1060 downloads) DSCN2478.jpg (43KB - 1060 downloads) DSCN2472.jpg (56KB - 1237 downloads) DSCN2472.jpg (56KB - 1237 downloads) | ||

| |||

| Traveling Man |

| ||

Finland, up there in north where noboby farms! | I have seen these machines parked in Kennewick, Wa and they are impressive. Couple miles hyd hoses!! They are sel leveling, aren't they. Any idea how much they weight? | ||

| |||

| Buster 50 |

| ||

North West IA/western AZ | They have really changed in 40 years! I worked summers for the Green Giant at Blue Earth. Back then they were pull type behind farm tractors the company rented from local farmers for the harvest. Also had smaller tractors with swathers on them. I worked in pest control mostly but after big rains we would get to help run tow tractors and pull the stuck machines out. Thanks for posting the pictures. Where do the vines come out now? Do they side dump on trucks? Edited by Buster 50 6/21/2009 14:47 | ||

| |||

| Jim |

| ||

Driftless SW Wisconsin | Most of those machines I haver seen running leave a windrow of pea straw right down the middle of the machine. Will someone please tell me why they do not put even a modest spreader on the back to spread the residue the width of the header????! Even if you moldboard plow this ground all that residue in one concentrated band is not good. Jim at Dawn Edited by Jim 6/21/2009 14:53 | ||

| |||

| Hop-a-long |

| ||

North West Kansas | They must weigh a bunch. Why don't they put the front on tracks to help with that? | ||

| |||

| Seed Grower |

| ||

Royal City, WA | I have farmed in eastern Washington, in the Columbia Basin, and have been around the green pea harvest for almost 40 years, and have had that same question about windrowing the residue. I have asked numerous fieldmen, and their reply is "That is the way the machines are made." When I ask them to request FMC (now Oxbo) if they would put on a residue spreader, they just say that is not their job or problem to deal with. There is a spreader of sorts on the back-it is an auger that spreads to both sides so it is about 4 feet wide. (It is not apparent from the pictures that these machines have the spreaders). What is even more frustrating is when one of the machines stops, the operator just sits there and lets the machine clean out and leaves a big pile that has to be spread by hand. Growers have requested that they give each machine operator a pitch fork, and when the machine is stopped and waiting for repair or to dump the peas, that the operator spread some of the piles. It is wasted words!!!! They have trouble getting enough operators to sit on their butts running the machines, let alone getting them to spread piles. We have much more vine than is in the pictures. Most years the vines are close to waist high if the vine is lifted up. If a farmer is no-tilling, it really can create problems. Most of the green peas are double-cropped with sweet corn or dry beans, and growers have to use coulters and residue cleaners to plant. Most still conventional till, and disc-rip, or disc and plow before planting. Depending on how wet the ground is when it is harvested, compaction can be a problem, and require tillage. This is an irrigated area, and if there is coordination between the fieldman and the grower, the moisture can be controlled prior to harvest. | ||

| |||

| Thud |

| ||

Near-north Ontario, French River | Hamachuck ( sp??) or as we called them Hammerclunks, used to run tracks on the front of the last machines they built. Great for in the field but an absolute nightmare when roading. The track system they had was poorly designed, the boggey wheels were mounted solid so the transmitted any an all vibrations directly to the machine when roading on asphalt. More then once I've seen bogeys; snap off when crossed raised rail road crossings. As others, I've often wondered why they dont add spreaders on the rear to spread of the vines, not sure why they dont do it ( its not lack of hydraulics thats for sure !) , but with the newer machines the vines coming out the back arent a real big deal unless the machine stops in one place for a bit, then they leave a large pile that must be spread out after the harvest crew leaves. Harvest started here in Ontario on Friday,yields from what I hear are so-so, supposed to start up again Monday. (Fmc1.jpg) (trackers2000b.jpg) Attachments ----------------  Fmc1.jpg (94KB - 1007 downloads) Fmc1.jpg (94KB - 1007 downloads) trackers2000b.jpg (109KB - 931 downloads) trackers2000b.jpg (109KB - 931 downloads) | ||

| |||

| Redman |

| ||

SW Saskatchewan | Any reason the pea vines couldn't be baled for cattle feed? If the weather is too hot and dry here the residue from the dry pea harvest breaks up to dust, otherwise it is baled and is a desired feed for beef cows. Quite deceiving, a little windrow of pea straw will make as much feed as a big fluffy cereal straw windrow. | ||

| |||

| Jay in WA |

| ||

Pasco WA. | I had some dandy windrows in my pea field. Took two passes with an offset disk to make a corn seedbed. Not many piles though because the operators would back the machines up while clean them out. That results in a larger windrow though. Vine spreaders would make life so much nicer. Compaction was s problem for me. The night before harvest we recieved a heavy thunder storm. | ||

| |||

| Thud |

| ||

Near-north Ontario, French River | In all my years of trucking peas I think I've seen the vines baled once, and that was last year, a very droughty year . I guess the guy had cattle and with the drought was figuring on being short of feed so he was baling about 24 hrs after the harvestors went through. | ||

| |||

| T800 |

| ||

Lee Co | I never got in on the podder-strippers as we called them but ran a windrower for 2 summers for Del monte back when they used hesston self propelled windrowers and the viners were pulled by a fleet of 2-105 whites. they would pull the fuse on the AC so it wouldn't work since the tractors only ran at a idle to drive slow enough but they were nice enough to remove the door and rear windowfor comfort. had a couple sothern boys that liked to read books while following windrows so on occasion I would cut crooked ones once even went in a circle to keep 'em awake on the night shift I worked. Brings back alot of memories.............. Edited by T800 6/21/2009 16:26 | ||

| |||

| Old Pokey |

| ||

| http://www.toytractortimes.com/tttsubscribe/litrkjune2004.htm Scroll down the page a bit and it will mention near 49,000lbs. | |||

| |||

| Jay in WA |

| ||

Pasco WA. | Pea vines make goo hay. The problem is that it takes quite a while to get them dry enough to bale and we are following with a second crop of sweet corn. With expensive fertilizer and cheap hay I also figured they are worth more as green manure. | ||

| |||

| Jon B |

| ||

| Although we didn't grow peas, we live in an hour or so drive from areas with a lot of pea production. Whenever I can, I stop and see the harvest. I have never been on a machine, but by the looks of it, it HAS to be an incredibly BORING job to do. Those machines seemingly crawl along at a snails pace. The guys that can do a good job deserve the cash, but they put in an aweful amount of hours to get the job done on time. Here are some pics from last year around the Chatham area. Edited by Jon B 6/21/2009 16:34 (P1000990(1).JPG) (P1000992(1).JPG) (P1000993(1).JPG) (P1000994(1).JPG) (P1000996(1).JPG) (P1000997(1).JPG) Attachments ----------------  P1000990(1).JPG (95KB - 882 downloads) P1000990(1).JPG (95KB - 882 downloads) P1000992(1).JPG (85KB - 912 downloads) P1000992(1).JPG (85KB - 912 downloads) P1000993(1).JPG (98KB - 815 downloads) P1000993(1).JPG (98KB - 815 downloads) P1000994(1).JPG (85KB - 939 downloads) P1000994(1).JPG (85KB - 939 downloads) P1000996(1).JPG (103KB - 881 downloads) P1000996(1).JPG (103KB - 881 downloads) P1000997(1).JPG (75KB - 940 downloads) P1000997(1).JPG (75KB - 940 downloads) | |||

| |||

| Grow |

| ||

| These harvesters should be pushing at least 30' heads and a bigger separator to handle the volume. Ground speed is a snails pace with these current harvesters. No wonder the operators are bored stiff sitting on these not wanting to spread a mound of tailings with a pitch fork. | |||

| |||

| Jim |

| ||

Driftless SW Wisconsin | I found a photo which shows us making Pluribus strips into harvested pea stubble. There has been some heavy rain in this heavy soil area in the couple days just ahead of making these strips. You can see we con get through it but look at the different amounts of residue even across the width of this 6R30 strip till machine. We are not entraining all this residue into the soil, differentially sucking/tying up N but it still is a good idea to spread that residue as close to the width of the head as possible. Here is the photo I found. Some of the residue in the distance fell back over the strip after we passed but not entrained and the planter row cleaners could sweep it aside, again. Why not just use a spreader???? Jim at Dawn Edited by Jim 6/21/2009 18:53 (Dawn_Strip till into MN pea stubble windrows_IMG_2558_1.JPG) (Dawn 7815 Strip Till Bar MN Pea ground.JPG) Attachments ----------------  Dawn_Strip till into MN pea stubble windrows_IMG_2558_1.JPG (125KB - 901 downloads) Dawn_Strip till into MN pea stubble windrows_IMG_2558_1.JPG (125KB - 901 downloads) Dawn 7815 Strip Till Bar MN Pea ground.JPG (82KB - 896 downloads) Dawn 7815 Strip Till Bar MN Pea ground.JPG (82KB - 896 downloads) | ||

| |||

| frmrzdotr |

| ||

| A little education... The peas we grow today are not at all like the peas from just 25 years ago. Basically, we have bred as many of the leaves off of them as possible, toughened up the vines, and created a plant that will grow well enough to set good pods yet leave all the vines and some of the leaves in the field without ever going through the harvester. The botanists call these "semi-leafless" peas. The "pod stripping" machines we run today do just that. They comb the vines and strip the pods and some leaves and of course a few vines go up into the machine. That way, the "windrow" is really very light on a dry matter basis and generally is not a problem without a spreader in place. Downtime piles and piles left at unload sites are still a pain, but for the most part the "windrow" is negligible after the sun does its thing. Because the windrow is so low on vine content, it doesn't bale worth a hoot and is not worth the effort. I don't know nearly enuff about the internals of the machine to explain why the headers aren't wider, but pea field yields will range from a few hundred pounds per acre to 8000+ pounds, so a wide machine would be impossible to slow down adequately in better yields. 3000-3800 pounds is a decent crop from what I remember. Still a good figure? fill me in, gentlemen... | |||

| |||

| Thud |

| ||

Near-north Ontario, French River | Slap a 30 ft head on one of the machines and the grass will be growing in the field faster then they can travel lol. Keep in mind that even with 12ft heads the harvestors are limited to between 1-2.5mph, 12ft heads are also about the limit in size for road travel, as well as being about the limit for in the field as the head must following to contour of the field precisely or low hanging pods ( often right on the ground) will be missed.. They take alot of wet material in the front, which leads to challenges in shelling and cleaning of the peas. | ||

| |||

| Plow79 |

| ||

Chilliwack BC | In this area, about 30 years ago almost all pea residue used to get gathered for cattle feed. My grandparents used to get a bit of pea silage from behind the combines. I know of others who made pea hay(they said it was the dustiest stuff ever). Maybe the mindset of the combine engineers just hasn't evolved from wanting the residue in the row, to spreading it. I guess that stuff happens when there's only one manufacturer of a piece of equipment. You get a monopoply and buyers can't switch colors because of failure to adapt. | ||

| |||

| paul the original |

| ||

southern MN | It takes a bit of hp to run a spreader; costs a few $1000 per machine to have one on. The folks owning/operating the pea pickers are interested in getting the most peas in the tin cans as cheaply as possible. They lease the land, and use it for their goals, bnot for good agronamy or good land use or ease of double-cropping or..... Typical lease vs own deal - someone leasing looks to short term goals, and not anyone else's needs or desires. Why would they bother to buy, operate, and maintain a spreader on all those machines when it returns nothing to them? --->Paul | ||

| |||

| racinfarmer |

| ||

| We have only been growing peas for a couple years, but we hit the piles with an older drag and it works fairly well. I've seen other farmers bring a skid and manure spreader out and put the piles in the spreaders and have at it. What we have done, and it workers well for us, is: -drag -disk and/or disk rip -finishing tillage pass -plant Piles are definatly a pain in the ass, but having operated one of the machines for a few hours, I have a whole new respect for the guys that do it. | |||

| |||

| Phil N |

| ||

| Great photos 2+2, thanks for sharing ! I used to work on a pea harvetst crew in England during the early 80's. We used to run 4x Mather & Platt MX Mk3 series viners. We used to pull them with +/- 150hp tractors. More recently everyone that still has peas have the self-propelled viners. Attached is a photo I took shortly after the drum came apart on a MX! I was near it when it came unglued. We never did figure what happend, but we thought the drum axle at the rear snapped, and it took a while to slow down from 250-300RPM ! Also attached is a newer series Ploeger viner also in England. Phil N http://www.needhamag.com/ Edited by Phil N 6/21/2009 23:01 (Petes MX Viner.jpg) (Ploeger 1.jpg) Attachments ----------------  Petes MX Viner.jpg (93KB - 970 downloads) Petes MX Viner.jpg (93KB - 970 downloads) Ploeger 1.jpg (97KB - 885 downloads) Ploeger 1.jpg (97KB - 885 downloads) | |||

| |||

| MN Dave 2 |

| ||

| My son drove pea combine for Green Giant in Blue Earth one summer 3-4 years ago. He was expected to be in field from 6PM to 6 AM with sometimes drive time from plant to field of an hour. He has some pretty good stories of getting combines stuck..... when plant needs peas to run, the combines WILL be moving, even if it is a sure thing to get stuck. One night he was dragging chains through water up to his waist to stuck combines. Each combine has a hopper that lifts up and dumps on truck. He said that if peas were contaminated with anything, they estimated pounds of peas so farmer got paid for them and then dumped them in field. One night he ran a skunk into combine and had to dump a almost full hopper load of peas. The newer combines use stripper heads. One header Matt was using had a lower auger that the flighting was so thin on that it would plug up very easy and when Matt would have to reach in to clean out, he would get his arms nicked/cut up. They had a same model parts head back at shop with a newer lower auger, it would take a couple of hours to change over, it would more than save time in the long run.... and you guesses it, the plant brain-wizzard wouldn't let them change it, they only had half of the year left. | |||

| |||

| HillsAre Us |

| ||

S.E. Minnesota | Last year I ran a Kuhn tedder across the field about as fast as I could hang on and it did break up and scatter the windrows and piles so no-till planting was then possible. I ended up spreading manure on pea fields and working it in anyway but it could have been no-tilled . | ||

| |||

| Jim |

| ||

Driftless SW Wisconsin | I still think a simple, old-time, combine type rubber tire strip spinning spreader would make a world of difference and could not add more than a couple hundred dollars to the cost of a pea harvester. It would save that many times over the first season. whether working the ground OR no till OR anything in between the spreader would even out the residue. Jim at Dawn | ||

| |||

| 2+2, MN |

| ||

New Ulm, MN | The windrows, My guess is FMC now OXBO, just dont care how the trash comes out, but to put a combine type spreader on wont work, the crop is harvested Green and very wet, the stuff the come out the back is very wet silage, You can actully see green water running out the back and from under neath, so it would just be to heavy to spread with a spinner spreader, the vine are short and most of what goes in is pods and some vine so the trash is not as thick as when i even started 10 years ago. Talked to a guy who ran a 2-135 white back in the day, the farm shop removed the AC belts, after a few nights he got sick of no AC 95 dgrees at midnight and humid, so he started bringing belts from home after a few nights he had the right one, so there whole crew would bring the belts in the lunch box wait for day shift crew boss to leave stop and put there belts on and go all night, take em off and go home at end of shift! | ||

| |||

| cynic |

| ||

| These pea combines strip the pods from the vines, leaving most of the vines where they grew. The windrow you see are the pods and do not seem to be a big problem for tillage. The old Hamachek combines took in the vines and pods from a windrow and did leave a big residue mass to deal with. That is no longer the case. | |||

| |||

| Jim |

| ||

Driftless SW Wisconsin | Your Quote:

I guess the key question her is what constitutes a "problem". Does this residue prevent you from running a tillage tool through the field after the pea harvest? No it does not usually, if this is what you are referring to as a problem. However this concentration of biomass in one windrow, whether worked in or not, is not good for the overall health of the soil. Any nitrogen in that windrow area tends to get tied up in the breakdown of that material much more so than in the more open areas to the sides of the windrow. It has long been know as important to distribute residue to approximately the same width as it came from (header width). Concentrations of residue like that are an agronomic problem, if not a physical problem. Here again is a photo I posted above. Look at the difference in the amount of residue, even though matted down from heavy rains, between the windrow and adjacent areas. If you look at the strips on the right, especially in the distance, you can see the difference in residue moved even clearer. As long as the strip till is not entraining that residue in the soil it is less of a problem. My point is that a very simple, low cost, 50-year-old-design combine-type spreader would greatly reduce or eliminate the entire issue. Jim at Dawn (Dawn_Strip till into MN pea stubble windrows_IMG_2558_1.JPG) Attachments ----------------  Dawn_Strip till into MN pea stubble windrows_IMG_2558_1.JPG (125KB - 971 downloads) Dawn_Strip till into MN pea stubble windrows_IMG_2558_1.JPG (125KB - 971 downloads) | ||

| |||

| Thud |

| ||

Near-north Ontario, French River | Jim one reason, and this is only a guess for not running spreaders is that the heads on these machines are only 12ft wide so the spread pattern would be relatively small anyway, so narrow that perhaps the spinner would be going so slow that the wet gooey gobs coming out the the machine would just build up on the spinner, insteat of being flung around. Now having said that the machines tend to run in echelons around the field. So no reason that the spread patterns couldnt be offet to one side, for instance set to spread 25ft wide pattern, directed to the side vs straight back. You would need the capability to shut off the spreader when breaking fields open etc as you wouldnt want to be spreading residue onto unharvested areas, or roads /adjoining lowns etc. As others have said the vast majority of the residue coming out the the harvestor is pods, and they tend to be ground up fairly well, the amount of actual residue is much less then it appears in the photos. | ||

| |||

| farmerjon52 |

| ||

| Jim, One way to set the combines is to check the "vines" coming out of the back of the combines to see if there are shelled peas coming out the back or peas unshelled left in the pods. If we spread them then I could not do that and I would not be able to walk behind each combine. Also, we harvest in some stoney areas and spreaders would create dangerous projectiles in the field. I am not a fan of this thinking but it is pretty much a "this is the way we have done this for years, so that's how we do it." It hard to add a $500 spreader on a $400,000 combine and justify the cost. HaHa, just kidding. | |||

| |||

| Jim |

| ||

Driftless SW Wisconsin | Jon, I'm looking at the other side of the coin, I guess. Many folks who have no-tilled corn into good wheat stubble that was harvested by a combine with no chaff spreader behind the cleaning shoe can show you a definite, visible difference in the corn which was planted in the windrow of chaff compared to corn which was planted behind a machine with a good chaff spreader. This is not even mentioning the straw. If that was our business, I would sell you a spreader that works for a whole lot less than $500! I think I've about beat this spread-the-windrow thing to death. Thanks for the comments. Jim at Dawn

Edited by Jim 6/22/2009 20:48 | ||

| |||

| Lenders |

| ||

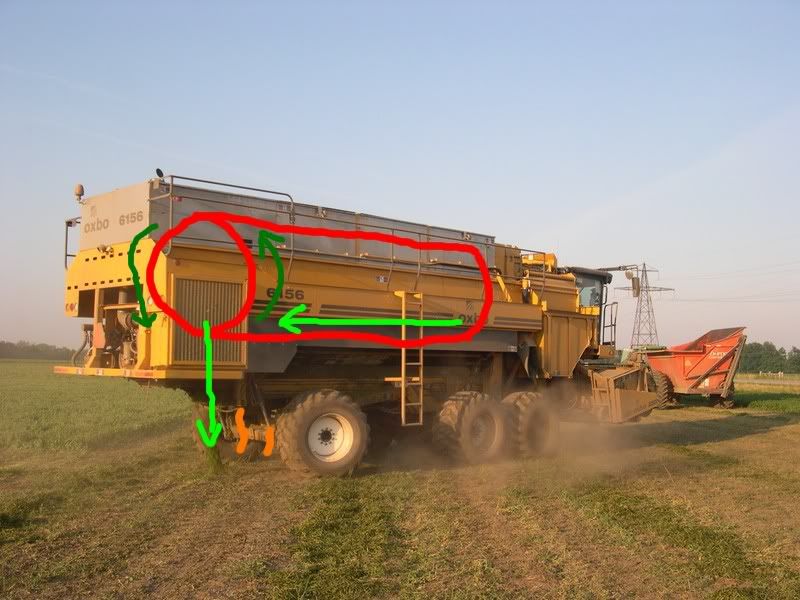

Dodge Co, Wi | Jim, it's just not very feasible to add. It would require mounting it to the rear axle to avoid interference with the levelling of the machine and be rather beefy to handle the mass of the vines/pods and getting it to only spread a 10' swath so as not to cover other peas it would spin so slow that the vines would just build up on it and burn out hydraulic motors. Also it would be in the way of climbing up the rear of the threshing reel to clean out plug-ups, as well as what Jon mentioned about checking for unthreshed peas.  the vines/pods just fall out of the end of the threshing reel and there is only about 18" of clearance between the engine and the end of the drum. The space between the two orange stripes changes constantly it will get shorter as the machine travels down hill and wider going up hill. The best way that I've seen to deal with the windrows is either to bale them, blow them into a wagon or run over them with a flail chopper just blowing/spreading them up in the air, once the rows have dried crispy they really blow apart with a flail mower. didn't see we had beat it to death, oh well. I know it is definitely a topic that gets brought up every year with the engineers from oxbo, as it would be nice to solve, i wish it were as simple as it looks to be. Edited by Lenders 6/22/2009 23:02 | ||

| |||

| Jim |

| ||

Driftless SW Wisconsin | Lenders, I appreciate your response, even including marking up a picture. I still do not see this as an insurmountable problem. A few of the combine guys I used to work with would have a working, reasonable cost, and safe spreader on that machine pretty quick. Maybe even without a 3-D computer model. If we look at this as a major problem how did we put men on the moon? Maybe everyone who used to solve these kinds of problems has been "early retired" out? Thanks for the comments even though I don't accept your conclusion. If you look at the man hours and units of nitrogen fertilizer those windrows waste there seems like an economic incentive to correct the problem/spread the windrow also. Jim at Dawn question: what does "OAC '04" stand for? Edited by Jim 6/23/2009 15:01 | ||

| |||

| Lenders |

| ||

Dodge Co, Wi | Jim, OAC (ontario agriculture college - university of guelph) class of 2004 (includes all aggies: bachelors of science/commerce/coupleothers). I know most harvest crews would be interested in a spreader, as they always catch heck from farmers for the windrows, especially in 2.5+ton peas. I mentioned it to the OXBO engineer when he was out to one of our fields 2 years ago, and he didn't have a real answer. If something could be mounted under there and not interfere with the levelling and be 100% reliable/ easily removable then there's no reason we couldn't do it, I think what it'll take is someone from outside our processing industry box to come in and look at the machines at work in the field and develop it from there. We've got a couple crews working up in the Hancock/Coloma region right now as well as N.Ill, I don't think we'll be into our local peas until the 10th or so, so it'll be a while before I can get at looking at them close up again. | ||

| |||

| J.Hasert |

| ||

Buster 50 - 6/21/2009 14:43 They have really changed in 40 years! I worked summers for the Green Giant at Blue Earth. Back then they were pull type behind farm tractors the company rented from local farmers for the harvest. Also had smaller tractors with swathers on them. I worked in pest control mostly but after big rains we would get to help run tow tractors and pull the stuck machines out. Thanks for posting the pictures. Where do the vines come out now? Do they side dump on trucks? Here are some pictures I have collected from days gone buy in WNY. I remember well one of the larger farms in town running 10 FMC pull type viners and one sp unit. They ran most of the viners on IH 1066's but neighbors were also hired to pull the combines so there was an M-M G-1355, JD 4020, Oliver 1755. They swathed the peas with three IH 275s. I wish I had more pictures from the pull type days.

| |||

| |||

| Buster 50 |

| ||

North West IA/western AZ | Never saw a SP model, but those pull type viners are the ones GG used. Thanks for posting the pictures. | ||

| |||

| Jump to page : 1 Now viewing page 1 [50 messages per page] |

| Search this forum Printer friendly version E-mail a link to this thread |

| (Delete cookies) | |